Drywall Basics

We spend a lot of time talking about the craft, technique, and business of drywall. We love looking at new tools and interesting gear, too. But when was the last time you thought about the drywall itself? Today, we’ll look at the drywall boards, what they’re made of, how they’ve evolved over the years, and look at a modern controversy in the industry.

History

Drywall was invented in 1916 by the United States Gypsum Company as a fast, inexpensive alternative to traditional plaster construction. Despite its modern construction, it still uses the same basic material that plaster works have always used: a powdery, white mineral called gypsum. While the very earliest forms of plaster used another mineral – lime – gypsum has been employed in plasterwork since the time of the Ancient Egyptians, as well as in Ancient Rome and throughout China and India.

The United States Gypsum Company’s innovation was to take a traditional raw material and manufacture it into standardized boards wrapped in paper. This allowed for faster, easier, cheaper construction of new buildings that still benefitted from plaster’s natural fire-resistant properties. Though the new material didn’t catch on immediately, drywall saw a boom in the post-war years as the population exploded and new construction had to keep pace with the increasing number of families that required homes.

In recent years, the emergence of drywall art has seen a return to some of the traditional plasterwork techniques employed by master craftsmen for centuries. Modern artisans who practice drywall art create sculptures and other custom artwork by shaping mud directly on the drywall board. These sculptures extend drywall’s role as a modern alternative to traditional plaster construction.

Types of Drywall and Modern Controversy

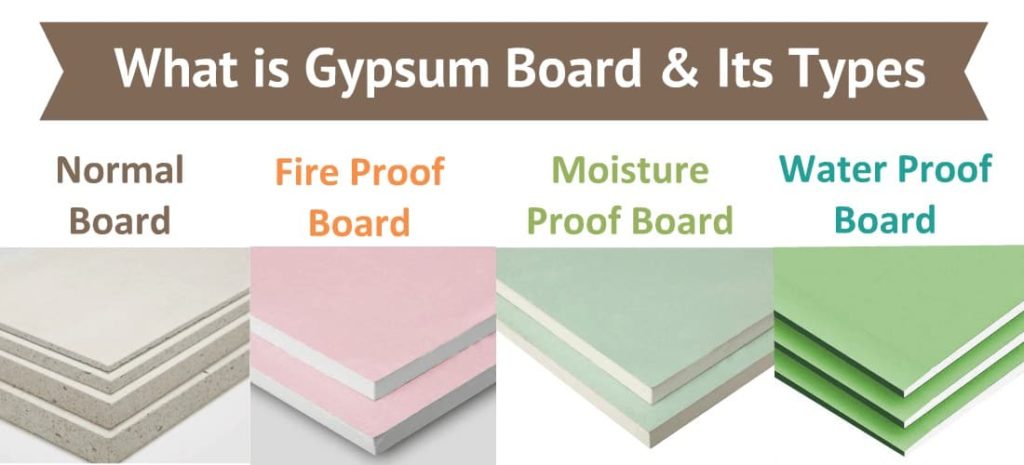

Over the last 100 years, the drywall boards have evolved to include lightweight, mold-resistant, moisture-resistant, and soundproof varieties, as well as specialized fire-resistant boards that improve on drywall’s natural fire-retardant properties with the addition of glass fibers.

But that’s not the only way that drywall has changed over the years. According to many in the industry, the last decade or so has seen changes to the drywall board’s construction. Finishing expert Rick Eisfeller explains, saying “it seems like the drywall itself – through the years – has changed. Outside shoulders are pressed and not rolled, so there’s a high spot there. The mud has to travel beyond that. A normal seam could have been 10″ in the 80s but now you need a 14″ box to hide the high shoulder.”

Complaints about the development of high shoulders aren’t new, though. In a 2007 article for Walls & Ceilings, Michael Gardner addresses the issue saying that “[w]hen faced with this predicament, wallboard finishers often assert that the board was manufactured incorrectly. Such is rarely the instance. Gypsum board is manufactured to strict tolerances by machines that are regularly calibrated to ensure that the product meets all required specifications. Any material that does not meet these specifications is taken out of the production line.”

Still, Eisfeller insists that “there’s bad drywall out there and you don’t know it until you start applying the mud…It’s just the way it’s made now but it’s harder for finishers. It makes me want to change my process, not do a Level 5 finish on every job.”

Eisfeller illustrates the problem best in saying, “If you put a power sander on it, you can see where it’s higher. It takes off the paper on most of the seams. I have to use all-purpose mud for the first two coats so it doesn’t burn through the paper.”

High shoulders aren’t the only problem that many professionals report. Some have seen drywall boards with air pockets inside that they fear will compromise the structural integrity of the board itself. Air pockets can also lead to more popped screws. In addition, Eisfeller says he’s seen changes to the paper used to wrap the gypsum. “Another thing is that the paper is textured. It’s not smooth anymore…The paper itself also seems to be thinner so there’s more nail pops and DIY guys are busting through the paper.”

Solutions for "Bad Boards"

As long as the problems persist, professionals will find solutions. As Eisfeller suggests, using all-purpose mud for the first two coats can help solve the sanding problem. For other issues, like the change in paper texture, Eisfeller recommends using a “really good primer or you’re skimming the whole wall out.” In some cases, the only solution is more time and effort. Speaking about the increased rate of nail pops, he says “you gotta pound that down. Just wiping mud over it doesn’t do it. And you’ve got to add more screws.”

Conclusion

There hasn’t been much official comment from manufacturers about the issues that Eisfeller and other professionals report. It’s hard to say for sure where the issue lies. On one hand, drywall manufacturing processes are tightly controlled. Drywall is a competitive business so manufacturing errors on the scale that many report would compromise millions of projects. That could hurt manufacturers’ image and would be a good reason to make sure problems with the boards were eliminated. On the other hand, professionals on the ground have eyes on the finished product and many have been working in the industry for decades, giving them a long-term view on product performance over time.